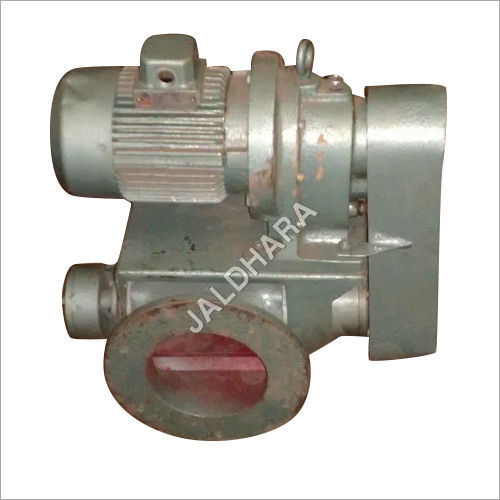

Rotary Airlock Valves

Price 25000.00 INR/ Piece

MOQ : 1 Piece

Rotary Airlock Valves Specification

- Application

- MATERIAL FINDING

- Working Temperature

- 80 Celsius (oC)

- Body Material

- Carbon Steel

- Usage

- INDUSTRIAL

- Material

- Casting

- Power

- Other

- Pressure

- Low Pressure

- Product Type

- INDUSTRIAL

- Weight

- 60 Kilograms (kg)

- Color

- aluminium paints

Rotary Airlock Valves Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- ahmedabad

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID), Western Union, Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Cash on Delivery (COD), Delivery Point (DP), Days after Acceptance (DA), Paypal, Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

- Packaging Details

- BOX PACKING

- Main Export Market(s)

- Africa, Asia

- Main Domestic Market

- All India

About Rotary Airlock Valves

We are betrothed in offering an excellent quality Rotary Airlock Valves. These valves are used for feeding material into a pneumatic conveying system. The provided valves are manufactured in strict adherence with predefined quality standards using optimal quality components and latest techniques. Furthermore, offered Rotary Airlock Valves are available in diverse specifications at reasonable rates.

Features:

- Optimum performance

- Low maintenance

- Tough construction

- Easy to install

Durable Construction for Industrial Needs

Manufactured from high-quality carbon steel and finished with aluminium paints, these rotary airlock valves stand up to industrial demands. Their casting body ensures superior resistance against wear and tear, providing long-term reliability for harsh environments.

Consistent Low-Pressure Performance

Designed specifically for low-pressure material transfer, these valves maintain an effective airlock, reducing air leakage. They help industrial plants to improve material flow control, ensuring efficient bulk material processing at working temperatures up to 80C.

FAQs of Rotary Airlock Valves:

Q: How should Rotary Airlock Valves be installed in industrial material handling systems?

A: Rotary Airlock Valves should be installed between the material discharge point and the conveying system. Proper alignment and sealing are vital to prevent air leakage and ensure continuous material flow. It is recommended to follow the manufacturers installation guidelines for best results.Q: What materials are used to manufacture these Rotary Airlock Valves?

A: These valves are constructed with a carbon steel body using advanced casting techniques and coated with aluminium paints. This combination ensures durability and resistance to corrosion, making the valves suitable for challenging industrial environments.Q: When is it necessary to use a Rotary Airlock Valve in an industrial process?

A: Use a Rotary Airlock Valve when you need to transfer bulk materials between containers or conveyors without disrupting air pressure. They are especially valuable for maintaining an air seal in low-pressure systems during material discharge or feeding.Q: Where are these Rotary Airlock Valves commonly utilized?

A: These valves are widely used in Indian industrial facilities dealing with bulk solids, such as material finding applications in processing plants, cement factories, and food industries. Distribution is available through authorized manufacturers, suppliers, and traders across India.Q: What is the typical process involved in maintaining a Rotary Airlock Valve?

A: Periodic maintenance includes checking for wear on the rotor and seals, ensuring the body remains free from blockages, and cleaning residues. Lubricate moving parts as specified and inspect for damage to maintain optimum performance.Q: What are the primary benefits of using Rotary Airlock Valves in industrial applications?

A: The main benefits include improved material flow control, minimized air leakage, reduced loss of material, and enhanced system efficiency. Their robust construction and temperature tolerance ensure long service life in demanding processes.Q: How much material weight can each Rotary Airlock Valve accommodate?

A: Each valve is designed to handle its own weight of 60 kilograms and is robust enough for continuous industrial use with a variety of bulk materials, as specified in the application requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Air Lock Valve Category

Rotary Air Lock Valve

Price 30000 INR / Set

Minimum Order Quantity : 1 Set

Material : Aluminum

Usage : Industrial

Size : Standard

Body Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese