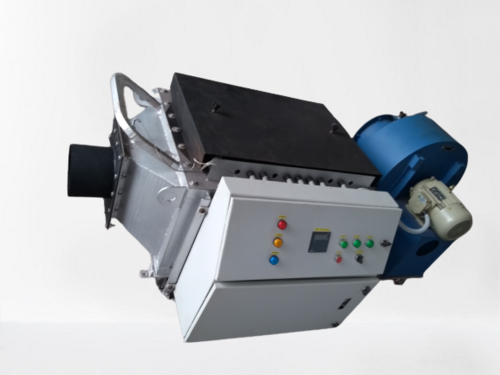

Trim Venturi Blower

Price 65000 INR/ Piece

Trim Venturi Blower Specification

- Motor Power

- 415 Volt (V)

- Power

- 415 Volt (v)

- Product Type

- Centrifugal Blower

- Material

- Steel

- Pressure

- High Pressure

- Application

- Packing, Filling, Thermoforming, Food-processing, prinitng, textile, Industrial, Air knives

- Frequency (MHz)

- 50 Hertz (HZ)

- Motor Speed

- 2880 RPM

- Noise Level

- 85 db

- Power Source

- Electric Blower

- Voltage

- 415 Volt (v)

- Color

- blue

- Warranty

- 1 YEAR

Trim Venturi Blower Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Paypal, Letter of Credit at Sight (Sight L/C), Cash on Delivery (COD), Days after Acceptance (DA), Cash Advance (CA), Delivery Point (DP), Cash in Advance (CID), Western Union, Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Set

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India

About Trim Venturi Blower

Our wide distribution network enable us to deliver this Trim Venturi Blower on time. The offered blower is manufactured using pristine quality components and modern techniques by our diligent professionals. This blower is mainly used to remove fumes, dust and waste particles from various places. Apart from this, our valued clients can avail this Trim Venturi Blower at reasonable prices within promised time frame. Trim Venturi Blower is extensively used at plastic industries, paper machinery and conveying pellets. It is operated with Direct & V belts for higher working efficiency. The industrial fan is compact and horizontal in design. This air blower has 300 CFM TO UP air volume capacity which helps in maintaining static pressure in area. It is easy to mount on walls and requires low maintenance.

Specification

- CAPACITY :300 CFM TO UP

- STATIC PRESSURE : 500 MM WG TO 1200 MM WG

- RPM :2880

- DRIVE : DIRECT,V BELT

- POWER :415 V

- MATERIAL : M.S,

- IMPELLER : ALUMINIUM, M.S

- APPLICATION :

- MATERIAL HANDLING, PLASTIC INDUSTRIES, PAPER MACHINERY, CONVEYING PELLETS ,

Features

- EASY MAINTENANCE

- LOW NOISEOPERATION

- LOW POWERCONSUMPTION

- HIGH EFFICIENCY

Reliable and Efficient Industrial Blower

Engineered for high-performance environments, the Trim Venturi Blower is ideal for various sectors requiring dependable airflow solutions. Its steel construction ensures longevity, while the powerful electric motor guarantees consistent operation. The product supports demanding applications found in food processing, textiles, packing, and more, serving as a versatile solution for Indian industries seeking high-pressure air delivery.

Applications Across Multiple Industries

This blower powers essential processes such as packing, thermoforming, and printing, making it valuable to manufacturers and industrial operations. Its design adapts to air knives and can streamline procedures in food-processing and textile production, enhancing overall efficiency and productivity. The combination of high motor speed and pressure ensures smooth operation even under rigorous conditions.

FAQs of Trim Venturi Blower:

Q: How is the Trim Venturi Blower used in industrial applications?

A: The Trim Venturi Blower is typically installed in industrial setups to provide controlled high-pressure airflow for processes such as packing, filling, thermoforming, food-processing, printing, textile manufacturing, and operating air knives. Its robust steel build and electric operation make it suitable for continuous, demanding usage.Q: What is the benefit of using a steel, high-pressure blower like this model?

A: The steel construction ensures durability and resistance to wear, making the blower ideal for heavy-duty industrial use. High-pressure capability enables more efficient and effective movement of air, ensuring processes like drying, cleaning, and material conveyance are performed optimally.Q: When should the Trim Venturi Blower be considered for replacement or servicing?

A: Generally, the blower should be serviced according to the manufacturers guidelines or when decreased performance is noticed. With a 1-year warranty provided, users are assured of support for any manufacturing defects or issues during the initial operational period.Q: Where can this blower be sourced in India?

A: The Trim Venturi Blower is available through established distributors, manufacturers, suppliers, and traders across India. Customers can purchase directly or contact authorized sellers for installation and support requirements.Q: What process is followed for installation and initial operation?

A: Installation typically involves secure placement, electrical connection to a 415 Volt power source, and setting up airflow ducts compatible with specific industrial requirements. It is advisable to have qualified technicians handle installation to ensure safety and efficiency.Q: How does the blower contribute to energy efficiency and workflow improvement?

A: With its electric motor tuned for industrial frequencies (50 Hz) and a speed of 2880 RPM, the blower offers strong air movement while maintaining energy efficiency. This leads to enhanced workflow and productivity by supporting faster and more uniform processing in various manufacturing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Blowers Category

Industrial BLOWER FAN

Price 22000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Motor Speed : 2880 RPM

Pressure : Low Pressure

Pressurization : Low Pressure

INDUSTRIAL HOT AIR BLOWER

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Motor Speed : 2880 RPM

Pressure : Medium Pressure

Pressurization : Medium Pressure

Industrial Air Blower

Price 22000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 YEAR

Motor Speed : 1440,2880 RPM

Pressure : Medium Pressure

Pressurization : Medium Pressure

Industrial BLOWER PUMP

Price 20000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Motor Speed : 2880 RPM

Pressure : Medium Pressure

Pressurization : Medium Pressure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese