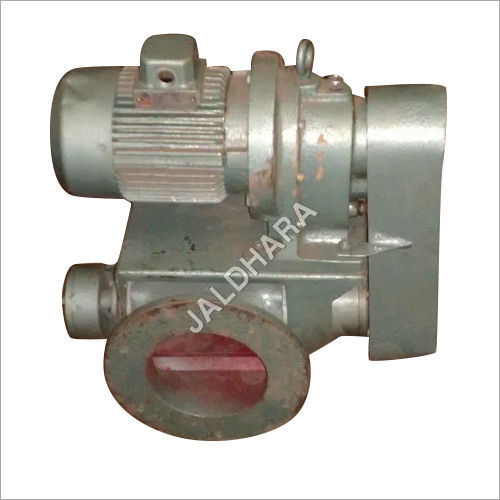

Rotary Air Lock Valve

Price 30000 INR/ Set

Rotary Air Lock Valve Specification

- Body Material

- Stainless Steel

- Media

- petroleum, Air, Oil

- Usage

- Industrial

- Material

- Aluminum

- Size

- Standard

- Product Type

- Rotary Air Lock Valve

- Color

- Silver

Rotary Air Lock Valve Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Month

- Delivery Time

- 7 Days

About Rotary Air Lock Valve

The absolute understanding of market demands has betrothed us to manufacture and supply a fine gamut of Rotary Air Lock Valve. The offered valve is used in dust control equipment and pneumatic conveying systems as volumetric feed-control. This valve is manufactured by our seasoned professionals using quality-approved raw materials and advanced techniques. It has a heavy duty design with thick castings, thick blade rotors with oversized shafts, outboard regreasable bearings, and gland type shaft seals. Applications of this Rotary Air Lock Valve vary from bottom of dust collectors to pneumatic conveying.

Features:

- Easy installation

- Rugged design

- Corrosion resistance

- Optimum finish

Rotary Air Lock Valve

The Drop Thru Rotary Airlock valve is the standard unit and used in most applications. These units are available in round or square. Jaldhara industries rotary airlocks are heavy duty design with thick castings, thick blade rotors with oversized shafts, outboard regreasable bearings, and gland type shaft seals. Numerous rotor options are available such as open end, closed end, fixed blades, adjustable blades, beveled edges, scalloped pockets, reduced volume, quick release, PTFE coated, abrasion resistant tips, flexible rubber tips, etc. Applications vary from bottom of dust collectors to pneumatic conveying.

Sizes available:

4, 6, 8, 10 & 12

Material : C I & S S 304,316

Reliable Industrial Solution

Our rotary air lock valves are engineered for optimal performance in challenging industrial scenarios. With aluminum and stainless steel construction, these valves provide long-term resilience, making them a dependable choice for managing media like oil, air, and petroleum. Their robust design minimizes maintenance and ensures sustained operation even in heavy-duty settings.

Versatile Application

The valves standard sizing and corrosion-resistant silver finish make it suitable for a wide range of industries throughout India. Whether you need a distributor, supplier, or trader, we offer prompt service and tailored solutions to fit your processing and handling systems.

FAQs of Rotary Air Lock Valve:

Q: How does a rotary air lock valve function in industrial applications?

A: A rotary air lock valve regulates the flow of bulk materials and mediasuch as petroleum, air, and oilbetween chambers of different pressure, preventing air leakage while enabling continuous material transfer.Q: What benefits do aluminum and stainless steel offer for rotary air lock valves?

A: The combination of aluminum and stainless steel offers excellent corrosion resistance, durability, and lightweight strength, making the valve suitable for rigorous industrial use and extending its operational lifespan.Q: When should you use a rotary air lock valve in your facility?

A: Rotary air lock valves should be used when you need to control the discharge of bulk materials and maintain pressure differentials in systems conveying petroleum, air, or oil, ensuring efficient and dust-free operation.Q: Where are your rotary air lock valves available in India?

A: As a trusted distributor, manufacturer, supplier, and trader, our rotary air lock valves are available across India. We ensure timely delivery and support for industrial clients nationwide.Q: What is the process for installing a rotary air lock valve?

A: Installation involves securely mounting the valve between system sections, connecting drive components, and ensuring all media inlets and outlets are properly sealed. Its essential to follow manufacturer guidelines for safe and efficient operation.Q: How is the rotary air lock valve maintained for optimal performance?

A: Routine maintenance includes periodic inspection for wear, timely lubrication, and cleaning to remove any build-up from handling petroleum, air, or oil. Regular servicing ensures uninterrupted operation and maximizes lifespan.Q: What are the main usage advantages of your rotary air lock valve?

A: The primary advantages include precise control of material flow, robust construction for industrial environments, compatibility with various media, and low maintenance needs, making it a cost-effective solution for bulk handling applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Lock Valve Category

Rotary Airlock Valves

Price 25000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Low Pressure

Material : Casting

Weight : 60 Kilograms (kg)

Working Temperature : 80 Celsius (oC)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese